ZERO-MIXING CONCEPT

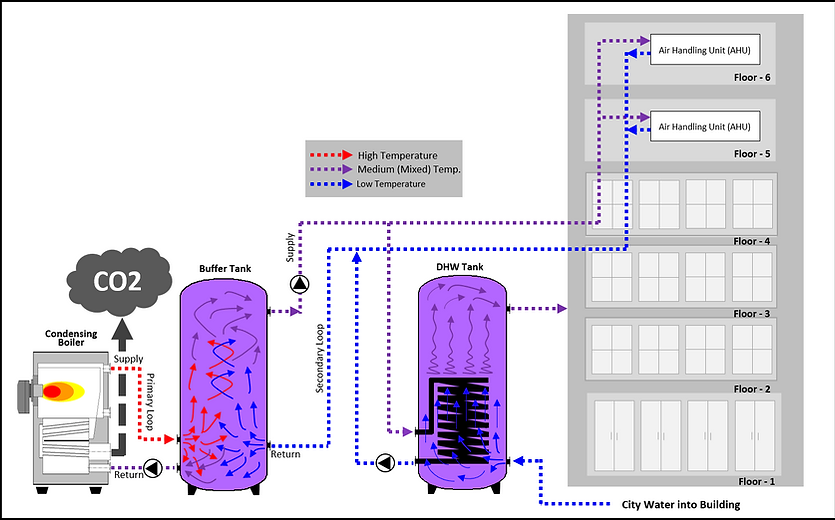

HVAC ZERO-MIXING technology eliminates water mixing from system hydronics maintaining a high temperature differential operation, maximizing heating/cooling generation and building distribution outputs, while sustaining high overall system efficiency [above 90% AFUE], independent of weather or any other building demanding conditions. ZERO-MIXING system utilize a Split Buffer Tank [SBF] to separate -decouple boiler hot water flow from warmer water flow from the building hydronic system, for outstanding improvement in building economy.

Modern buildings [including high-performance LEED/Zero-Carbon-Certified ZCB buildings] operate with HVAC technologies that run on an INEFFICIENT-INEFFECTIVE Water-Mixing platform that impacts heating/cooling generation and building equipment distribution capabilities. The results, low water temperature differential operation [between 20˚C to 10˚C] limiting equipment output, efficiency and the temperature controlling process. Building economy gets impacted by the unnecessary consumption of non-renewable, HVAC-electricity, and much higher CO2 emissions.

Current Commercial Technology

Zero- Mixing Concept

SYSTEM HEAT LOAD ADVANTAGE

Laboratory test on Zero-Mixing/Commercial twin systems proved that the boiler/Split Buffer Tank [SBT] system outperformed the boiler/Commercial system output by 50%, delivering 100% load at a fraction of the time. The boiler/Commercial system had to perform a second 30-minute run to match the boiler/SBT system output, triggering two additional/differential purges in the process. The boiler/SBT system ZERO MIXING emulation test proved that it is possible to provide the system with continuous boiler high-temperature water output and obtain in the process a low-water return back to the boiler for reheating while maintaining SSET efficient operation.

THE FLOW ADVANTAGE

Advantages offered by the Water-Mixing elimination allows the boiler/SBT system operation to run at a maximum SSET temperature differential (up to 52°C) on both primary and secondary loops, resulting in reduced pumping and air-handling flows without sacrificing boiler, AHU, or VAVs max output. The new boiler/SBT system low-flow/high-temperature differential design offers to retrofitted system substantial savings on electricity bills from reduced pumping capacity and AHU/VAV-box air-fan operation.

Current HVAC design fundamentals on condensing boiler-systems reinforce the practice of boilers’ output settings that call for 20°C/10°C reset-temperature differentials. Despite various literature suggested advantages, reset-differential limits hot-water production capacity while forcing the system to operate at unnecessary pumping higher-flow volumes on both primary and secondary loops. A low HVAC boiler-system temperature differential operation also diminished water conditions for optimum heat output from ancillary equipment (AHU heating coils, VAV-box heating coils, radiant slabs heating, hot water baseboards, snow-melt system or any other devices used for heat delivery). Such limitations force secondary system terminal units not only to work harder but also for longer periods of time to provide building comfort; or in the case of industrial setting, limiting optimum process set-point conditions, sacrificing production output and quality.

SYSTEM CONTROL ADVANTAGE

There are many ways to control a boiler and ways boiler controls can be layered. A boiler’s own controls can be set for standalone operation to maintain desired boiler set-points, and also can be linked to a more complex Direct Digital Control (DDC) system for a multi-boiler multi-stage with more complex controlling operation. Customary use of DDC-OCR controls to manage boiler output, coupled with temperature controlled variable flow pumps to produce low temperature water return for boiler condensing opportunities, always result in water mixing in the supply heater. No matter what strategy is used, multi-stage boiler lead/lag, boiler lead/lag with demand or boiler multi-pump rotation/operational sequencing, boiler(s) at some point during operation are forced to over-fire (short-cycle) due to mixing.

SBT system integration and on-stream reading, with sensors location TS1/TS2/TS3/TS4 at the inlets/outlets of the tank, allows accurate input/output temperature measurements and signaling back to the boiler(s) and building’s pumps, eliminating problems associated to manifold temperature sensor misreading. Since boiler supply and building return flows are contained within the SBT, water mixing will never occur nor the associated signaling problems.

HOW ZERO-MIXING SYSTEM WORKS

With the exception of HVAC Primary-only systems, most systems today are configured with a primary loop to reheat recirculating water from the buffer to the boiler, and a secondary loop to supply hot water from the buffer to the building, and warm-water back to the buffer. The lack of a mechanical barrier to control the encounter of both flows inside hydronics and buffers allow water mixing to happen. It is in this process that mixed water flows are directed to unintended HVAC components with different entering water temperature requirements jeopardizing the efficiency of the equipment and the system as a whole.

In an HVAC Primary-only systems, the buffer tank in the figure above represent the system thermal mass, rather than the actual physical tank. The limited thermal mass in this type of systems, along with the presence of water mixing, jeopardize equipment output, operating efficiency and creates opportunities for boiler cycling. Primary-only systems run at efficiencies between 60% to 75% AFUE.

Typical Modern HVAC System

New HVAC Zero-Mixing System

HVAC boiler - Split Buffer Tank systems’ operation eliminates the Water Mixing phenomenon very common in existing installations today. The ZERO-MIXING concept it uses helps to revise current engineering fundamentals, closing the gap between conceptual design and actual system performance. Like no other devise in the market, the Split Buffer Tank [SBT] integration into a newly developed or old retrofitted system resolves the boiler-system SSET-test efficiency conundrum and brings real-life performance closer to high-efficiency test conditions.

The system implementation of the ZERO MIXING concept along with SBT integration provides the tools necessary to sustain building HVAC continuous efficient operation (as high as 95% AFUE).